Stay on plan.

Every unit. Every shift. Every work order.

Busroot connects directly to your machines, comparing actual performance against your production plan in real time.

Know instantly when you're off track. Get production back on plan, fast.

Why it matters

Plans are worthless without execution. Busroot keeps you on track.

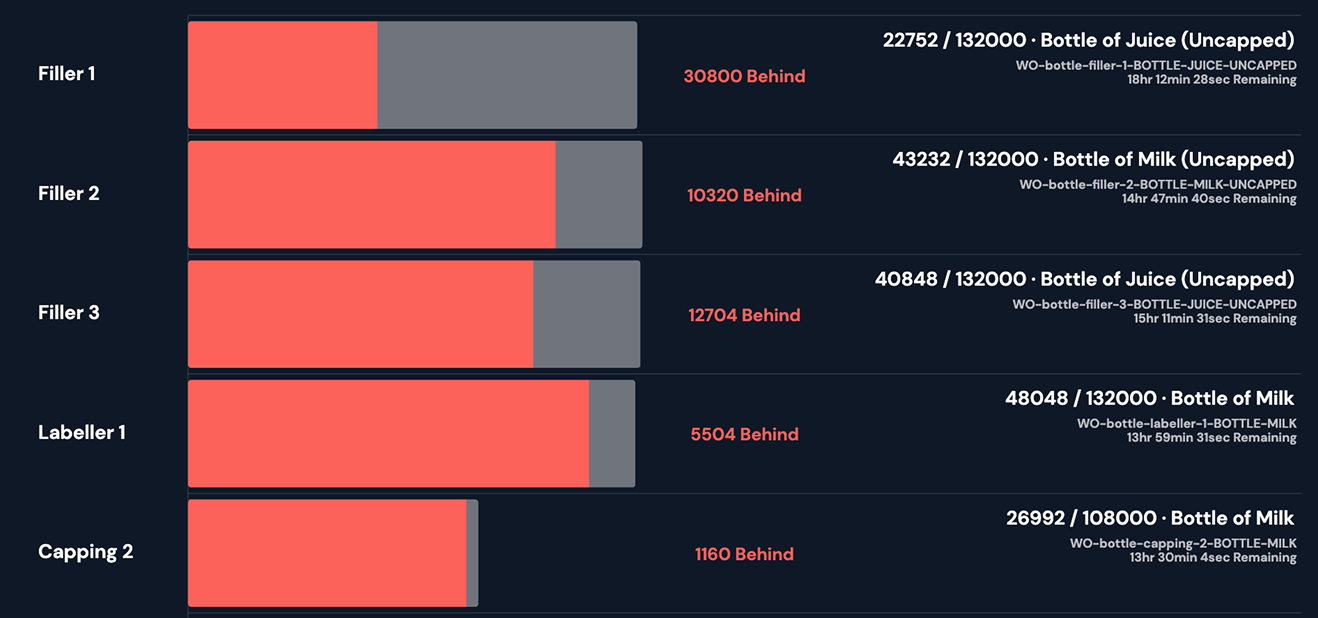

Plan vs. Actual

Compare real-time performance against your production plan - know exactly where you stand, every shift.

Instant alerts

Get notified the moment production falls behind plan - act before small delays become big problems.

Rapid correction

Spot issues as they happen and respond with clarity - get production back on track, fast.

What it does

Track what’s being made.

Understand how it’s performing.

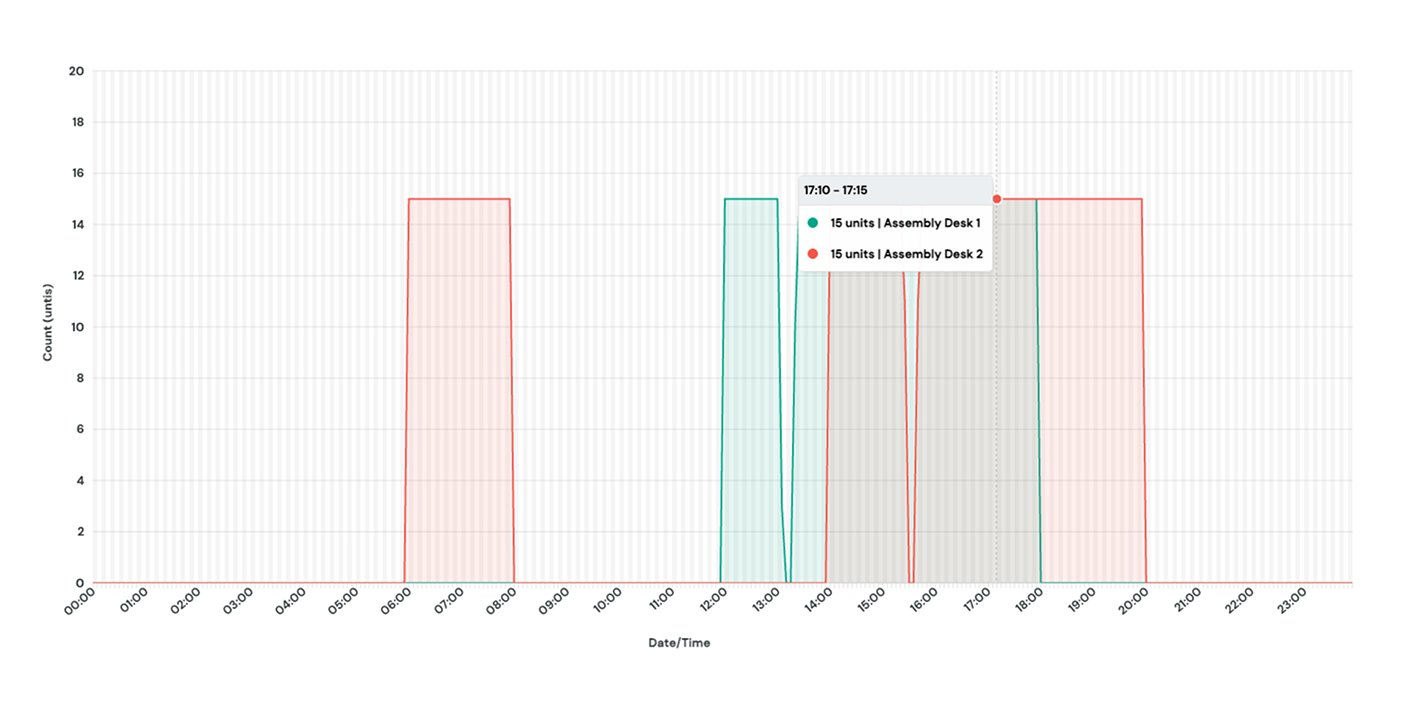

Live production tracking

See output as it happens. Unit-by-unit, shift-by-shift, line-by-line.

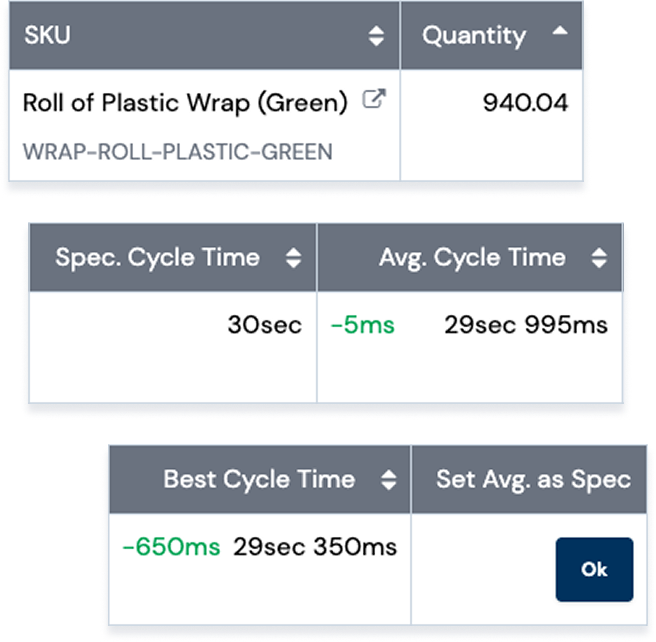

Cycle time analysis

Track actual cycle times against standard. Highlight variances instantly.

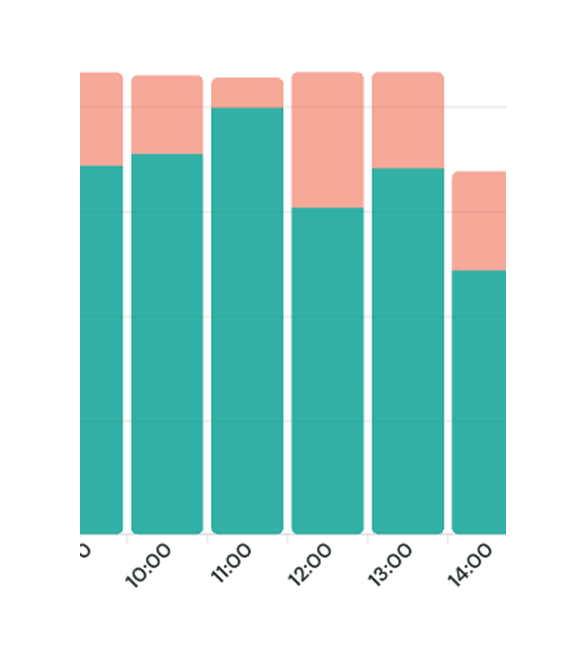

Short interval control

Break the shift into actionable windows. Review, react, and improve fast.

Work order and shift performance

Track actuals against plan in real time—stay ahead of delays and overruns.

Trend analysis

Spot patterns in performance over time. Compare shifts, lines, and SKUs.

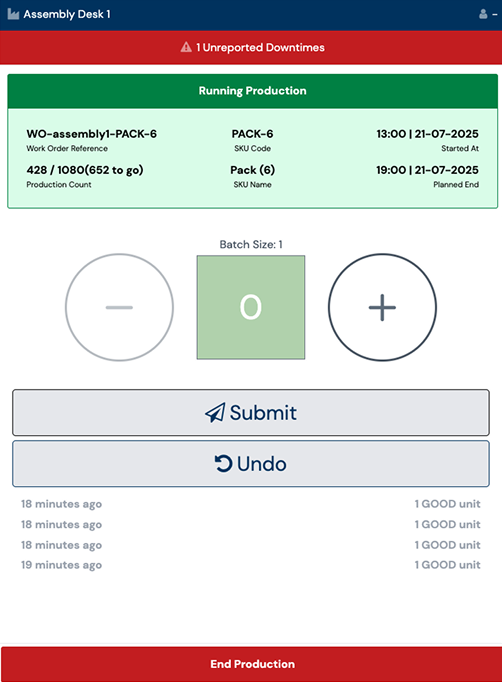

Operator interface

Capture context from the floor—without interrupting the flow.

FAQs

Everything you need to know to get started.

Can Busroot monitor my production process?

Yes. Busroot tracks output in units, boxes, litres, metres—whatever you produce. Whether you're running batch, flow, or discrete production, we’ll help you capture the right data.

What hardware is required for each machine or line?

You’ll need a Busroot-compatible device like the Arduino Opta and a network connection. We’ll help you select and set up what’s needed—no specialist equipment required.

How long does it take to go live?

You’ll be connected in minutes. Most sites are fully live within 1–2 days.

Can it track different SKUs and work orders?

Yes. You can track by SKU, work order, shift, or line—and compare performance across all of them.

What if operators need to add context?

Busroot includes a simple operator input interface. Add corrections or downtime reasons—without slowing the line.

How does this replace manual reporting?

Live dashboards replace spreadsheets and whiteboards. Get accurate data without chasing it down.

What do you need to know about my production process?

To configure Busroot for your site, we’ll ask a few key questions:

- What machines are you connecting?

- What do you want to track (units, time, metres, etc.)?

- What are your shift times and cycle times?

- What are your typical downtime reasons?

- Which SKUs do you make, and how are they structured inside a work order?

We’ll handle the rest—so your setup matches your process from day one.

“The insights we get from Busroot have helped us spot clear opportunities to improve efficiency and boost productivity.”

Richard, Group Production Director

ADEY Steel

“Busroot has helped us increase utilisation, output, and efficiency - all without growing our headcount.”

Bobby, Senior Engineering Manager

TEREX

Ready to boost performance and cut waste?

Book your demo and see how Busroot unlocks visibility, accountability, and real-time action - without disrupting your operation.