Detect downtime in real time.

Know when. Know why. Take action.

Busroot automatically logs unplanned stops, capturing both the moment it happened and the reason behind it - live from the factory floor.

No assumptions. No chasing answers. Just clear, actionable data.

Why it matters

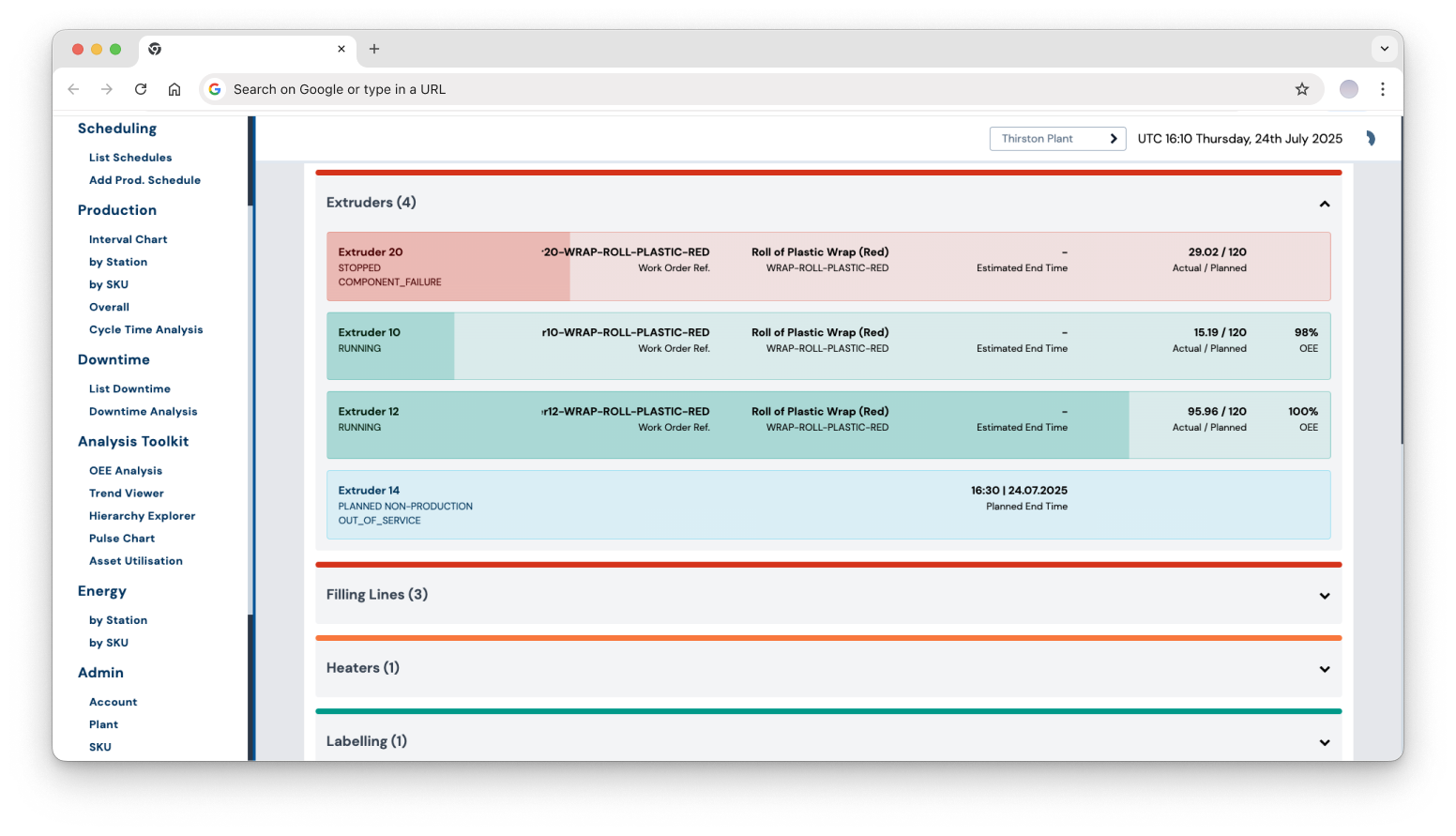

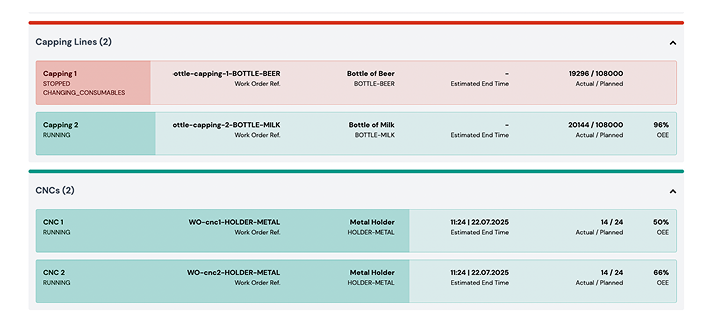

Track what’s being made. Understand how it’s performing.

See the moment a machine goes down - no delays, no missed events.

Capture the real reasons behind downtime and share a single source of truth.

Act quickly with real-time alerts and clear downtime context.

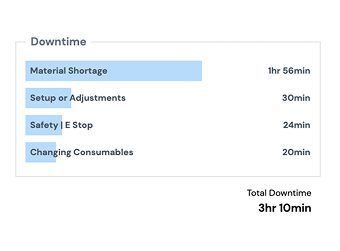

Use downtime trends to reduce disruption, improve reliability, and boost OEE.

What it does

Track when downtime occurs.

Understand why it happened.

Automatic downtime detection

Busroot picks up changes in machine state and logs downtime instantly.

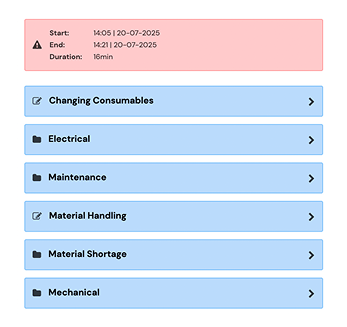

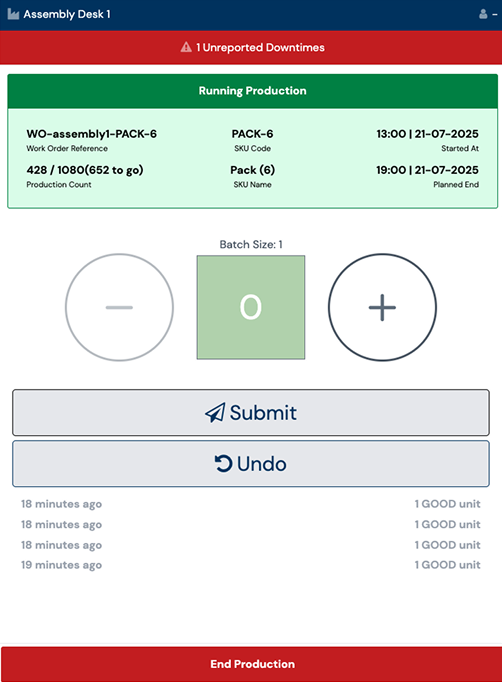

Operator input & reason codes

Operators can quickly assign a reason - so you get context, not just a timestamp.

Downtime categorisation

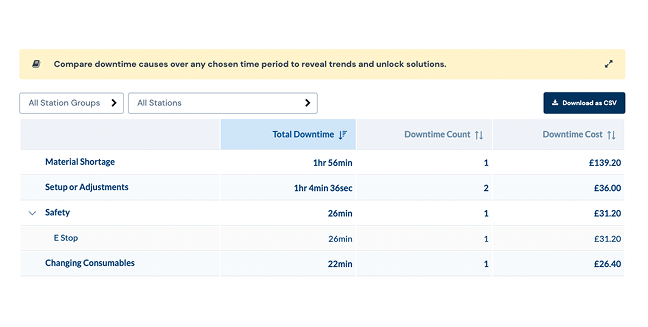

Group stops by type (e.g. mechanical, material, planned) for clearer analysis.

Root cause analysis

Drill into trends to understand what’s driving the most frequent or costly stops.

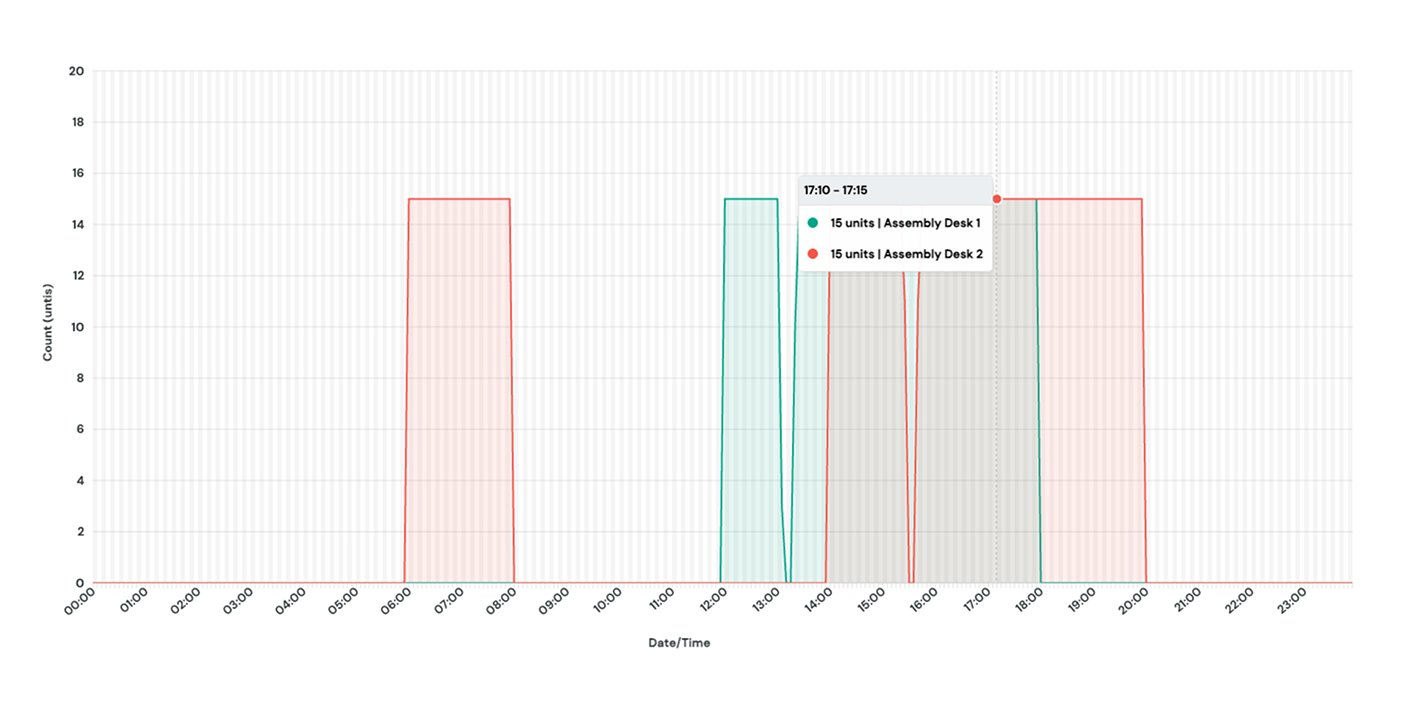

Visual timelines

See when downtime happened across the shift and spot recurring patterns.

Real-time alerts

Get notified when a machine goes down - so action can be taken immediately.

FAQs

Everything you need to know to get started.

How does Busroot detect downtime?

Busroot monitors machine state in real time. Thresholds can be set at the machine or SKU level. When a threshold is met, downtime is logged automatically - no manual tracking required.

Can operators add downtime reasons?

Yes. Operators can assign a reason code or add context in seconds using the operator interface - without interrupting the line.

Can we customise the downtime reason codes?

Absolutely. You can define your own reason codes to reflect your operation - planned maintenance, material shortage, breakdown, and more.

Will we get notified when a machine goes down?

Yes. You can set up real-time alerts when a machine stops, exceeds a downtime threshold, or fails to recover in time.

Can we view downtime trends over time?

Yes. Busroot provides visual timelines and reports to spot recurring issues by line, shift, machine, or reason.

Does downtime tracking work with any machine?

Yes. Busroot is hardware-agnostic and works with standard sensors - no need for proprietary hardware.

Is it possible to capture a reason code directly from the machine without operator intervention?

Yes. If your machine or PLC provides status signals, Busroot can automatically assign a reason code based on those signals - no operator input needed.

“We’re utilising data from Busroot through Excel and pivot tables, reviewing it weekly. In those meetings, we identify the biggest offenders and tackle the problem. This results in minimised downtime and improved efficiency.”

Jakub, Continuous Improvement Manager

Belvoir

“Using Busroot has helped us gain invaluable insight into our cut shop operations as part of our digital roadmap improvements. We have been able to increase our utilisation, output and efficiency without increasing the headcount.”

Matthew ‘Bobby’ Taylor, Senior Engineering Manager

TEREX

Ready to boost performance and cut waste?

Book your demo and see how Busroot unlocks visibility, accountability, and real-time action - without disrupting your operation.