Belvoir Farm cuts

downtime by 70%

downtime by 70%

Busroot gave the team real-time visibility into bottlenecks – what’s slowing them down, how bad it is, and how to fix it fast.

FOOD & BEVERAGE

Belvoir Farm produces premium soft drinks using natural ingredients – specialising in presses, cordials, and botanical blends.

BOTTLING & BLENDING

A fast-moving operation blending fresh ingredients and bottling at scale, with a focus on quality, consistency, and sustainability.

LEICESTERSHIRE, UK

A rural, purpose-built facility powered by renewable energy – rooted in British farming heritage, supplying retailers nationwide.

The challenge

Guesswork, paper trails, and reactive fixes.

When downtime started eating into production targets, spreadsheets and instinct weren’t enough. Belvoir needed a live view of what was slowing things down – how bad it was, and how to fix it fast.

1. Unknown Downtime

Despite measuring OEE, the team struggled to stay ahead of downtime.

2. Unmanageable Paperwork

Handwritten logs were cumbersome and prone to errors.

3. Delayed Reaction

Insights were delayed, forcing reactive decision-making.

From guesswork to real-time clarity

When downtime started eating into production targets, spreadsheets and instinct weren’t enough. Belvoir needed a live view of what was slowing things down - how bad it was, and how to fix it fast.

Faced with persistent downtime and limited visibility, Belvoir Farm needed more than gut instinct and lagging spreadsheets. They needed a clear, live picture of what was happening on the factory floor - and why.

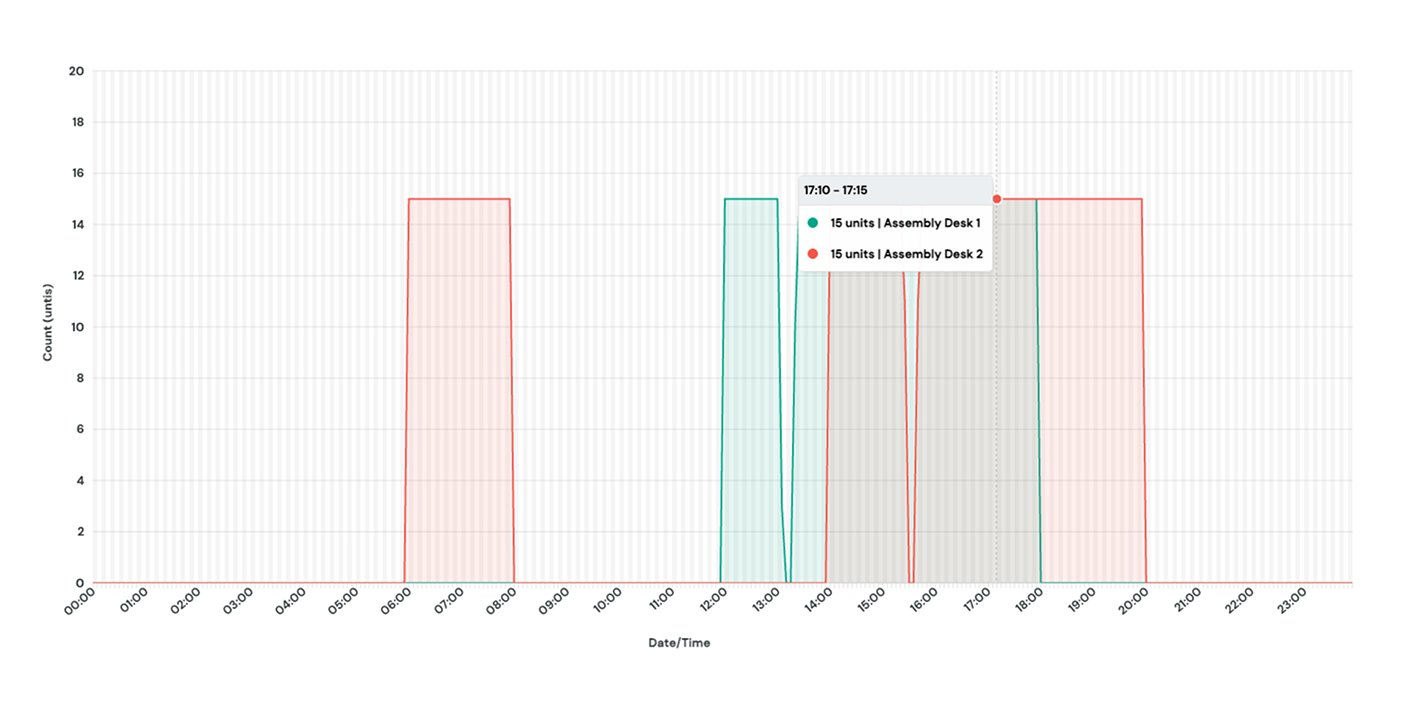

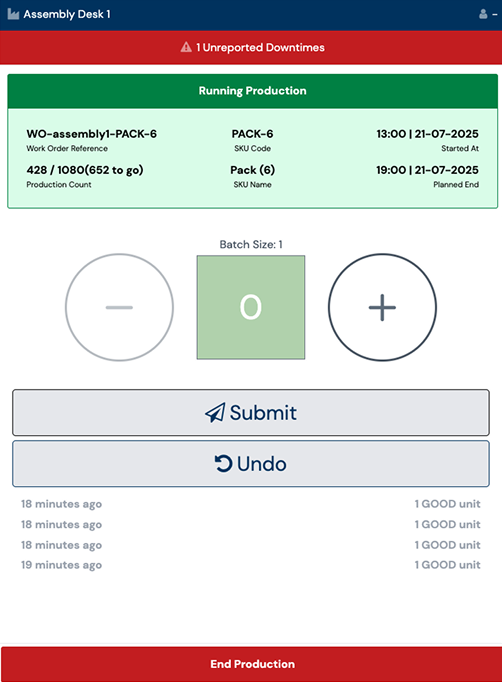

Within just one month of installing Busroot, the team pinpointed a recurring issue on their depalletizer. With data to back them up, they identified mechanical faults and gaps in operator training that had been dragging performance down.

Instead of reacting after the fact, Belvoir’s team could now prioritise the fixes that mattered most - leading to a 70% reduction in downtime on that machine alone. And that was just the start.

With Busroot in place, the team began weekly reviews of production data, using one live dashboard to make smarter, faster decisions - without chasing paper or second-guessing what was going wrong

70%

Downtime reduction on the depalletizer in just one month - driven by real-time visibility and alerts.

100%

...digital. From paper logs to live dashboards - with Busroot now powering a paperless QMS in the pipeline.

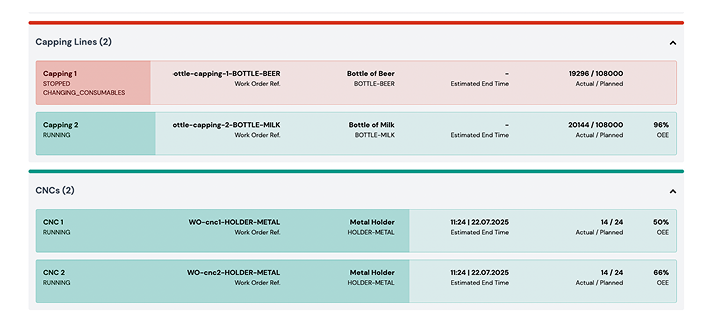

Automatic downtime detection

Busroot picks up changes in machine state and logs downtime instantly

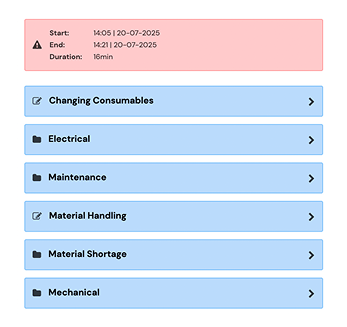

Operator input & reason codes

Operators can quickly assign a reason - so you get context, not just a timestamp

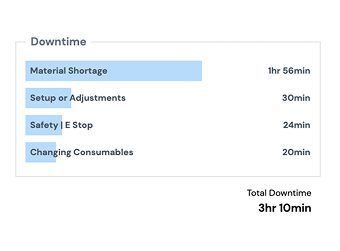

Downtime categorisation

Group stops by type (e.g mechanical, material, planned) for clearer analysis.

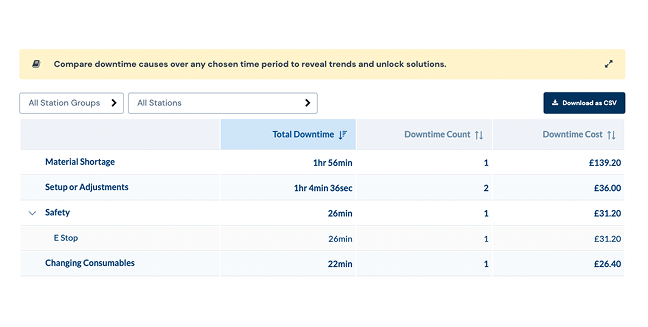

Root cause analysis

Drill into trends to understand what's driving the most frequent or costly stops.

Visual timelines

See when downtime happened across the shift and spot recurring patterns

Real-time alerts

Get notified when a machine goes down - action can be taken immediately.

“We’re utilising data from Busroot through Excel and pivot tables, reviewing it weekly. In those meetings, we identify the biggest offenders and tackle the problem. This results in minimised downtime and improved efficiency.”

Jakub

Continous Improvement Manager

“Belvoir’s team moved fast - within weeks, they’d gone fully digital and uncovered a key bottleneck. Busroot helped reduce downtime by 70%, and they’ve not looked back since.”

Harry

Technical Support Engineer

Ready to boost performance and cut waste?

Book your demo and see how Busroot unlocks visibility, accountability, and real-time action - without disrupting your operation.